UK Client Visit Case | Apple Cabin Production Inspection & Shipment Confirmation

This week, Shandong Shanghe welcomed a client delegation from the United Kingdom to inspect our Apple Cabin production line and confirm shipment arrangements.

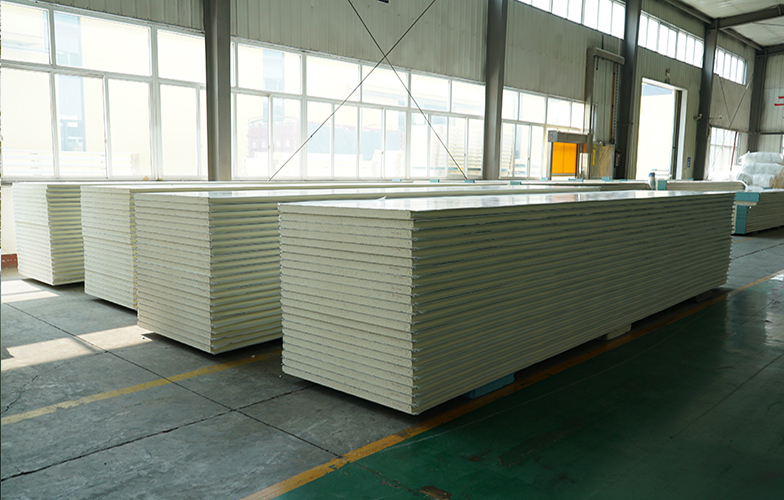

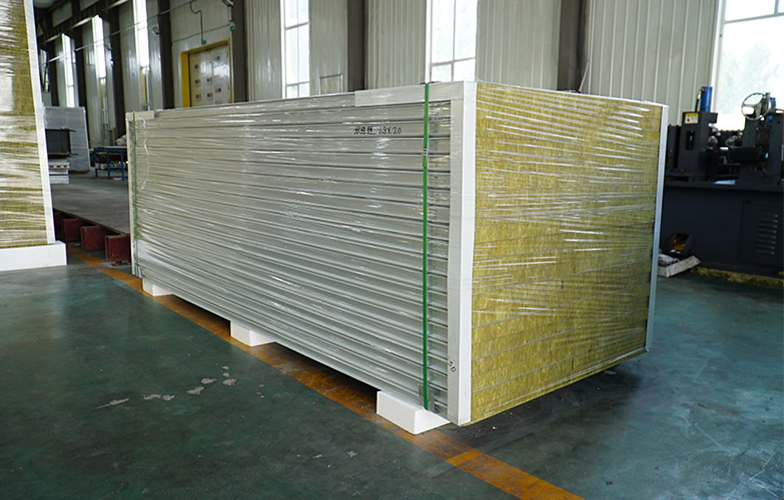

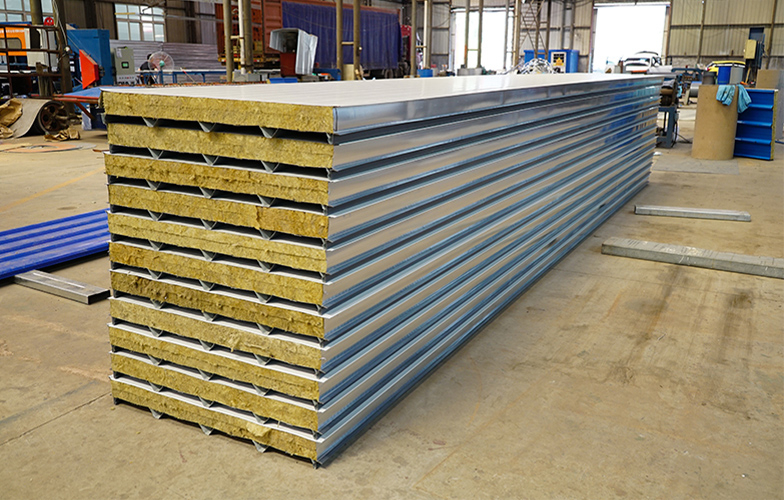

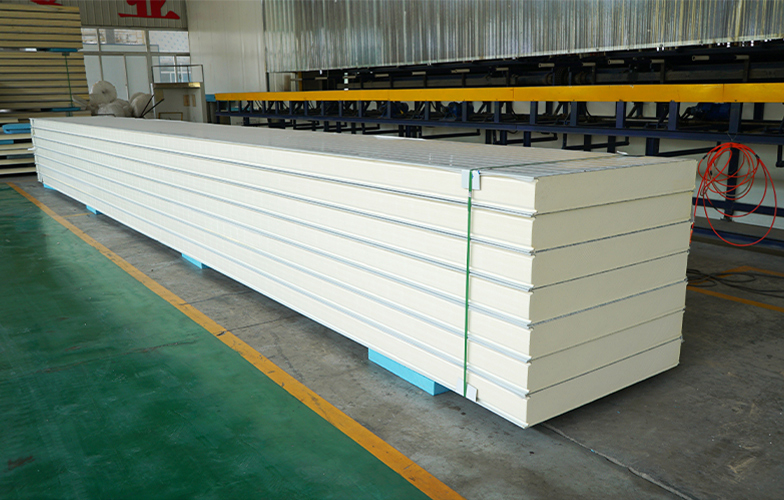

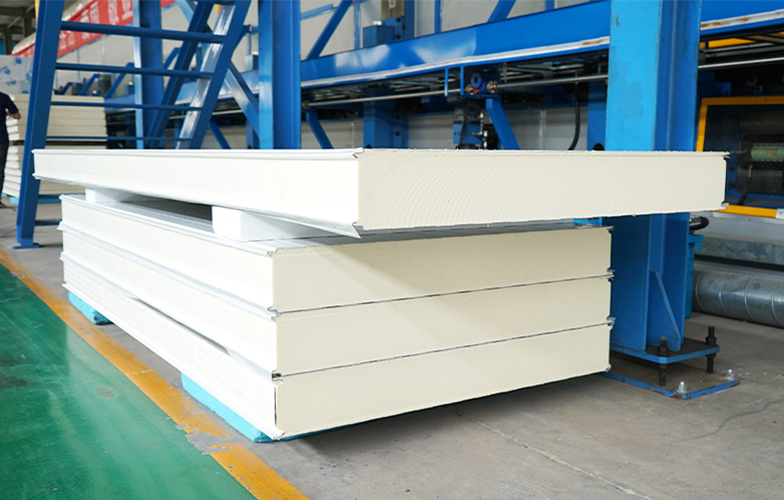

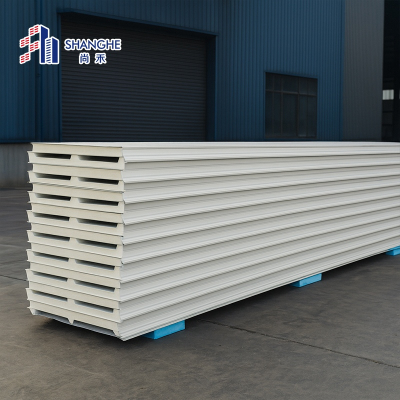

Upon arrival, the UK team was guided through the complete manufacturing process — from steel structure fabrication and wall assembly to interior finishing, electrical installation, and final quality inspection. They carefully checked details such as structural welding, surface finishing, insulation layers, window installation, and interior layout.

During the visit, the clients paid special attention to:

Cabin structure stability

Thermal insulation performance

Electrical system configuration

Interior finishing quality

Waterproofing and sealing process

They were impressed by the overall build quality, installation precision, and strong production capability of our Apple Cabin units.

After completing the production inspection, both sides moved to the loading area to review packing standards and container-loading procedures. The client team confirmed the shipment condition on-site, including protective packaging, fixing methods, and loading layout, ensuring safe transportation for long-distance sea shipping.

A detailed face-to-face discussion followed, covering:

Delivery schedule

Shipping documentation

Custom configuration for future orders

After-sales support plan

The visit concluded successfully with shipment approval and future cooperation planning. The UK client expressed high confidence in Shandong Shanghe’s product quality, production management, and delivery reliability.

Shandong Shanghe sincerely appreciates the visit and trust from our UK partners. We will continue delivering high-quality Apple Cabin solutions to the global market.

For factory visits, production inspection, or shipment arrangements, feel free to contact us.