Fire-resistant rock wall sandwich panel designed for industrial and commercial wall insulation

High-performance rock wool sandwich panel for wall insulation with excellent thermal and acoustic performance

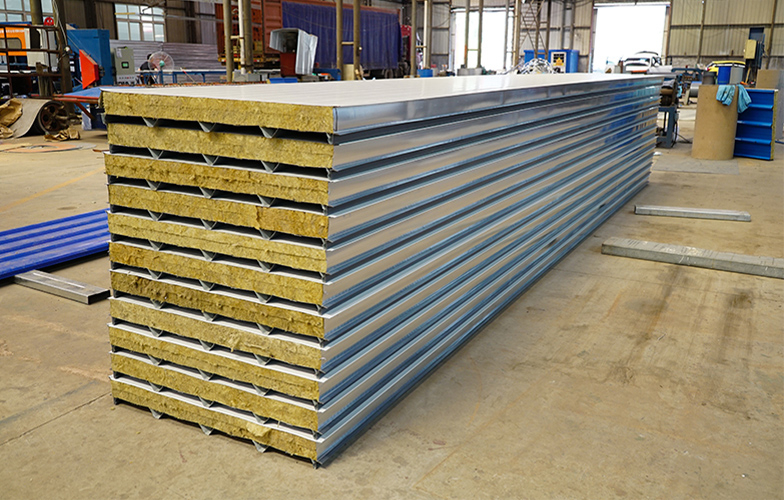

Manufactured using top-grade mineral wool to ensure A1-grade fire resistance

Rock wool sandwich wall panels suitable for cleanrooms, laboratories, food processing areas, and pharmaceutical facilities

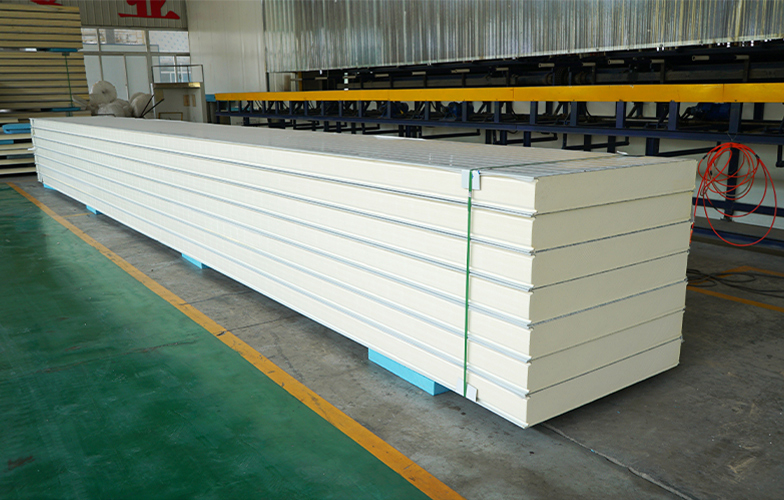

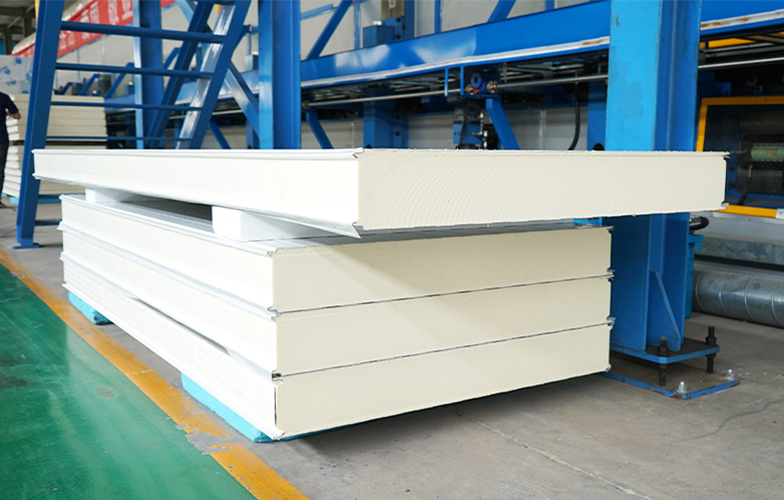

Strong structural panel with steel-faced layers and concealed joint systems for airtight wall construction

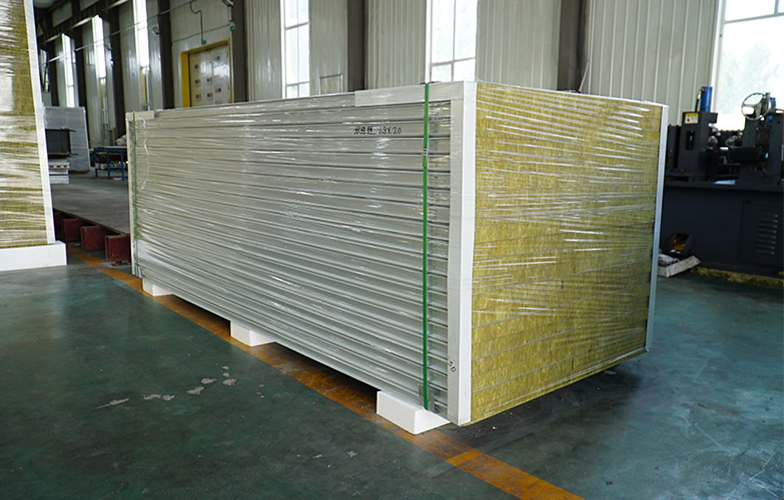

Factory-direct supply with customizable thickness, width, length, and steel surface materials

Our rock wall sandwich panel series is engineered to provide exceptional fire resistance, sound insulation, and thermal efficiency for modern building wall systems.

As a top-quality solution, the rock wool sandwich panel for wall insulation uses high-density rock wool core material that offers A1-level fireproof capability, making it ideal for high-safety buildings.

Rock wool sandwich wall panels deliver stable temperature control, noise reduction, and excellent moisture resistance, making them widely used in warehouses, industrial plants, cleanrooms, pharmaceutical facilities, and food-grade environments.

The rock wool wall sandwich panel for cleanroom applications offers superior cleanliness performance, smooth surfaces, and concealed joint systems to maintain contamination control requirements.

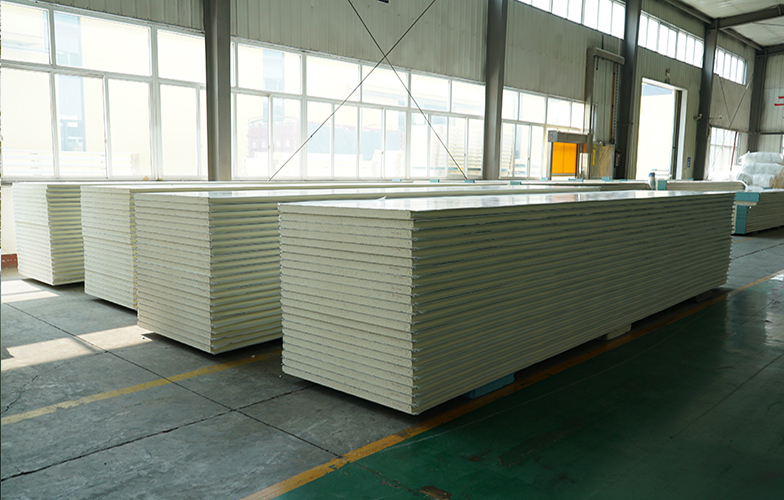

We operate a modern automated production facility dedicated to manufacturing rock wool sandwich wall panels for global construction projects.

Continuous sandwich panel production lines

Automated rock wool cutting and lamination systems

Advanced roll forming machines for steel profiling

High precision CNC cutting for customized panel dimensions

OEM and ODM production capabilities

ISO9001 and ISO14001 certified manufacturing processes

Rock wool density testing

Bonding strength and adhesion testing

Fire resistance classification (A1-grade)

Thermal conductivity verification

Steel sheet corrosion resistance testing

Dimensional accuracy and joint alignment checks

As a professional manufacturer, we support project-based customization and global export supply.

| Item | Specification |

Core Material | High-density rock wool |

Density | 100–150 kg/m³ |

Standard Width | 950 mm, 960 mm, 1000 mm |

Panel Length | Custom up to 12 meters |

Panel Thickness | 50 mm, 75 mm, 100 mm, 120 mm, 150 mm |

Thermal Conductivity | ≤ 0.038 W/(m·K) |

Fire Rating | A1 Non-combustible |

Steel Sheet Thickness | 0.35–0.7 mm |

Steel Surface Options | PPGI, GI, PPGL, Stainless steel |

Joint Type | Concealed fix, tongue-and-groove |

Soundproof Rating | ≥ 30 dB depending on thickness |

Applications | Cleanrooms, industrial walls, cold rooms, commercial buildings |

Cleanroom wall systems (pharmaceutical | semiconductor | medical)

Industrial fireproof walls

Warehouse partition walls

Cold room and food processing facilities

Soundproof wall structures

Commercial building exterior and interior walls

High-temperature and fire-resistant construction projects

Excellent A1-class fireproof performance

Superior thermal and sound insulation

Durable steel-facing with corrosion resistance

Hygienic, easy-to-clean finish perfect for cleanrooms

Fast installation with secure interlocking joints

Factory-direct pricing with flexible customization

Engineering support for large commercial and industrial projects

A1 Yes, they achieve A1-grade fire resistance, making them ideal for high-safety buildings.

A2 Yes, the rock wool wall sandwich panel for cleanroom applications is designed with smooth, hygienic surfaces and airtight joints.

A3 Standard options include 50–150 mm, and custom thickness is available.

A4 Yes, steel surface colors (RAL chart) and lengths up to 12 meters can be customized.

A5 Yes, we export rock wool sandwich wall panels to over 60 countries with fast delivery.