Rapid Assembly and Disassembly:Modular structure allows repeated installation and relocation with minimal labor.

Container-Based Steel Framework:High-strength steel panels and beams ensure structural stability and long service life.

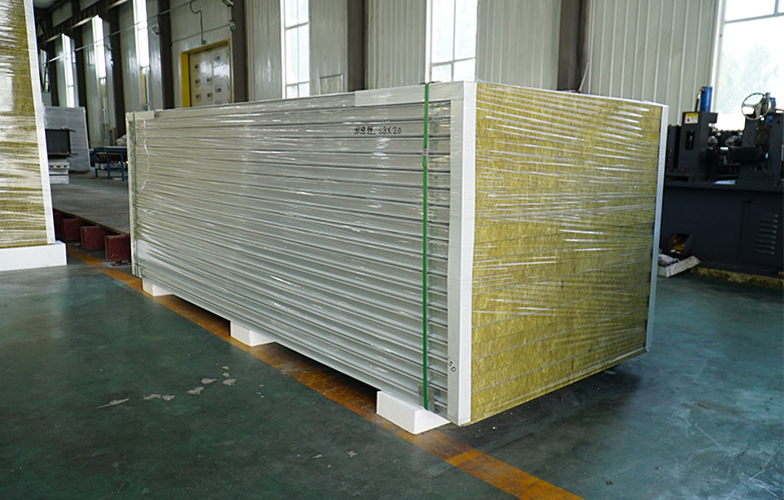

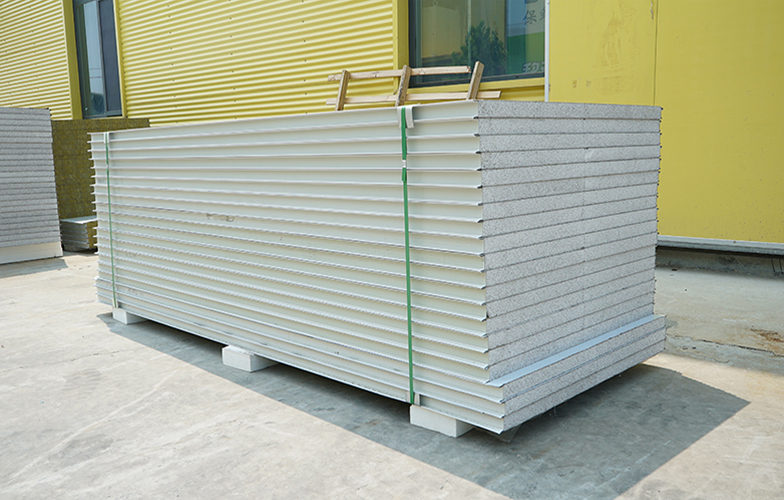

Lower Shipping Cost:Flat-pack design reduces container volume and international freight expenses.

Flexible Layout Configurations:Units can be linked, expanded, or rearranged based on project needs.

Weather-Resistant Structure:Designed to withstand wind, rain, and temperature variation in various regions.

Storage container houses Product Details

The Storage container houses stands as a practical, cost-effective modular building solution, engineered to deliver flexible usability and rapid deployment—ideal for scenarios demanding agility and efficiency.

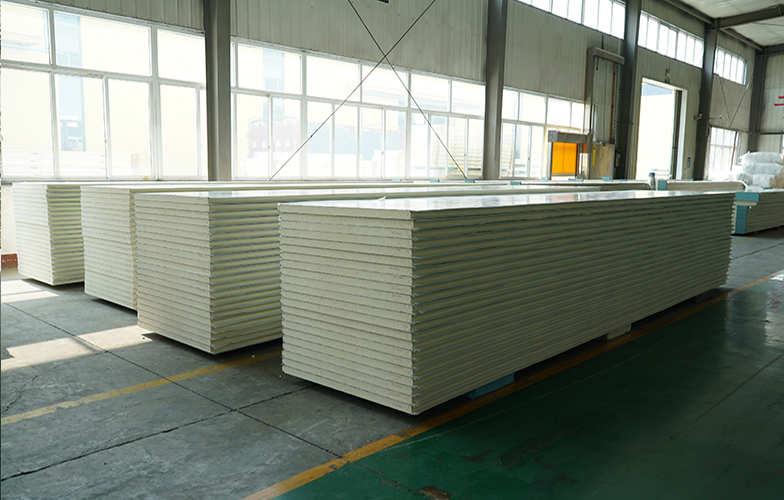

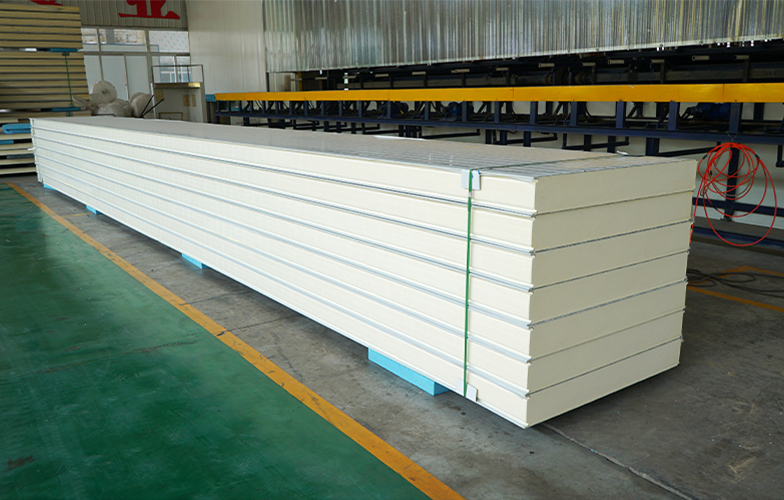

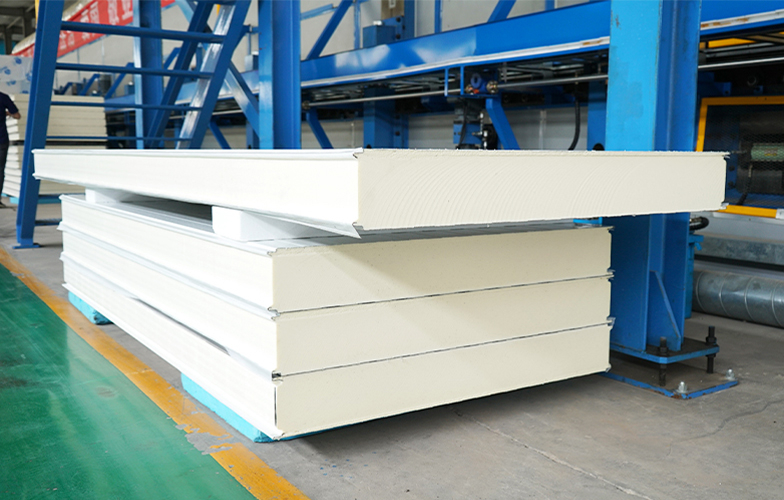

Distinct from traditional welded container houses, this innovative structure is constructed from standardized panels and beams, designed for on-site assembly. All core components are shipped in flat-pack form, which not only drastically reduces freight expenses but also enhances logistical efficiency—particularly valuable for overseas projects.

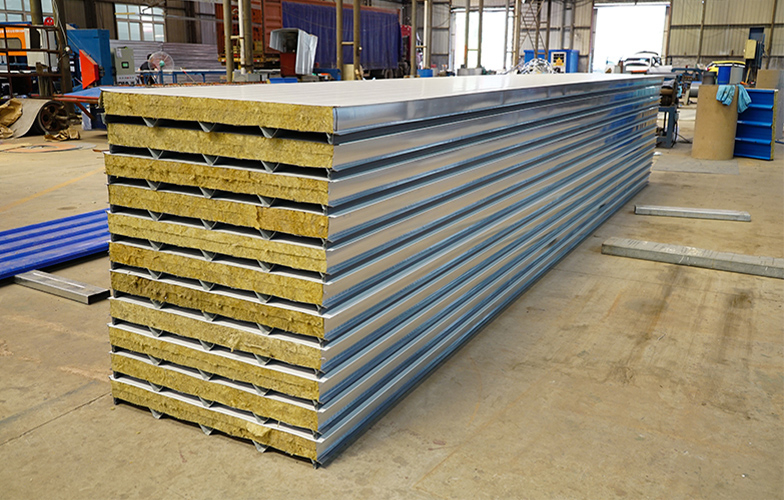

Its structural system is built around reinforced steel frames, providing exceptional load-bearing capacity and strong resistance to deformation. The wall and roof panels typically adopt insulated sandwich structures, which not only boost thermal insulation performance but also effectively reduce noise transmission. Thanks to its sealed design, the building maintains stable indoor conditions even in challenging environments such as coastal areas, deserts, or frigid regions.

Interior planning prioritizes functionality and durability. Electrical wiring, lighting fixtures, distribution boxes, windows, doors, and drainage systems can be either pre-installed at the factory or assembled on-site, depending on specific project requirements. The interior finishes are easy to clean and maintain, making the unit well-suited for frequent relocation or high-traffic usage scenarios. Additionally, the flooring materials are carefully selected for their anti-slip, waterproof, and abrasion-resistant properties, ensuring long-term reliability.

Installation is streamlined and straightforward. A foundation using concrete pads, slab bases, or steel supports is generally sufficient to meet requirements. Following frame assembly, panels are fixed in place, followed by roof installation and system connections. A trained team can complete the assembly process within hours, depending on the unit’s size and configuration. Disassembly follows the reverse sequence, enabling highly efficient reuse and transportation.