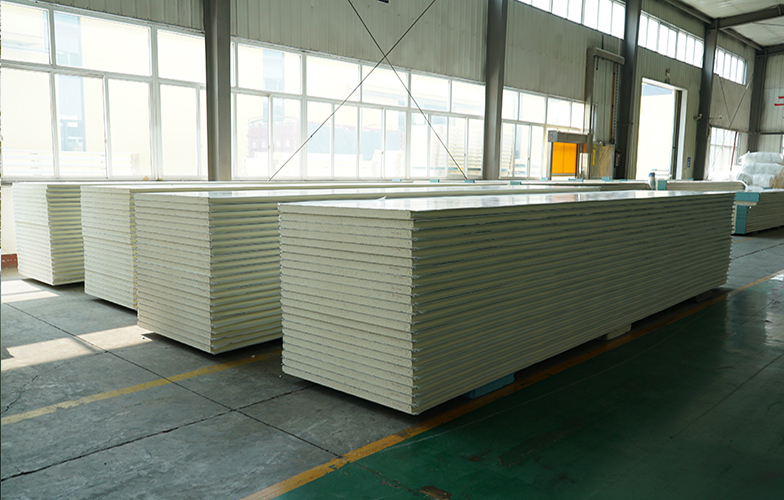

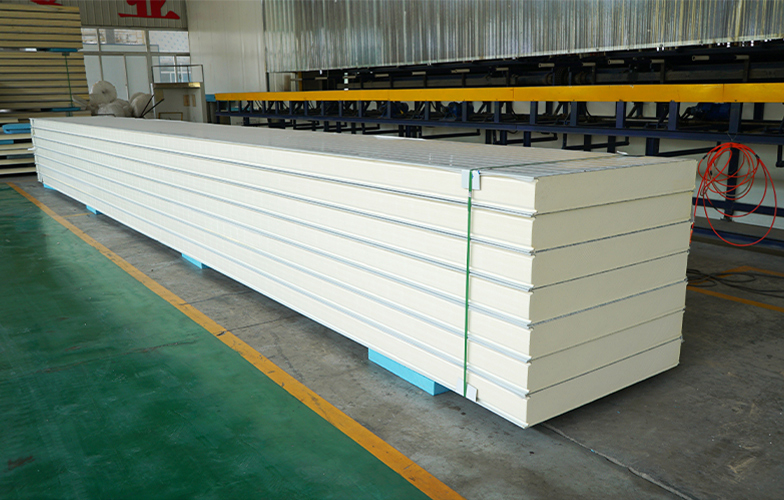

Fully customized OEM sandwich panels for walls designed for industrial, commercial, and cold room wall structures

Specialized production for customized sandwich panels for cold room partition wall with precise insulation performance

Manufactured by a professional team focusing on customized sandwich panels walls for various construction projects

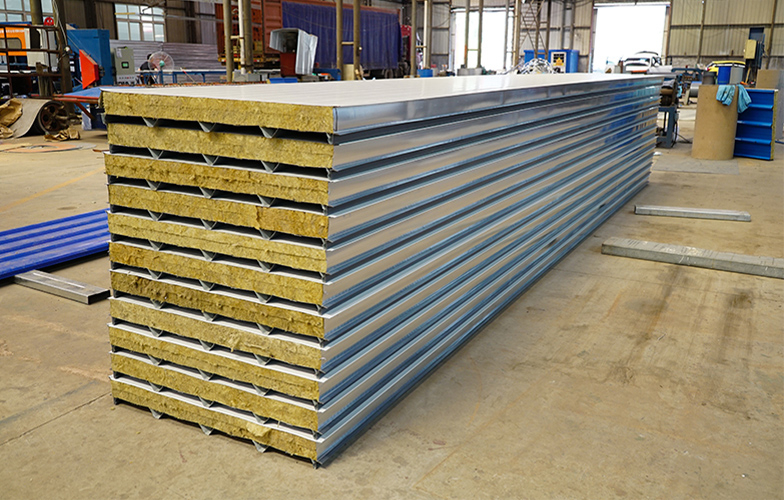

High-quality customized wall sandwich panel options including PU, PIR, EPS, and rock wool cores

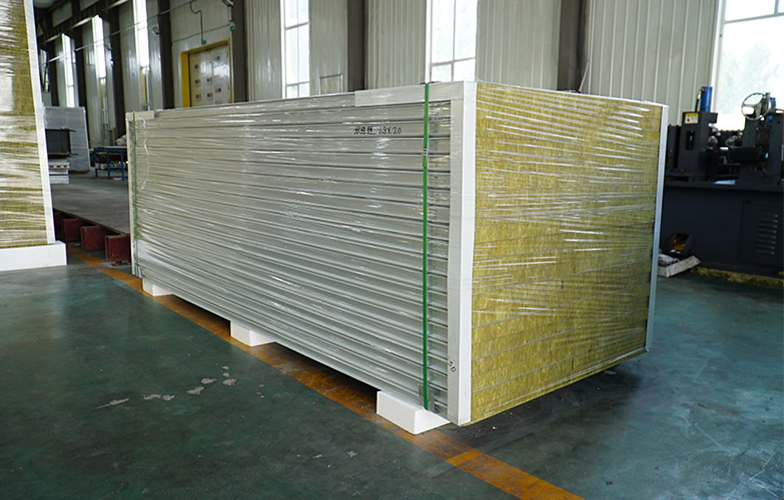

Factory direct pricing, fast delivery, and complete customization for thickness, length, color, and steel material

Suitable for commercial buildings, cold rooms, warehouses, modular houses, clean rooms, and exterior wall systems

Our customized OEM sandwich panels for walls are engineered to provide exceptional insulation, structural stability, and versatility for modern construction applications.

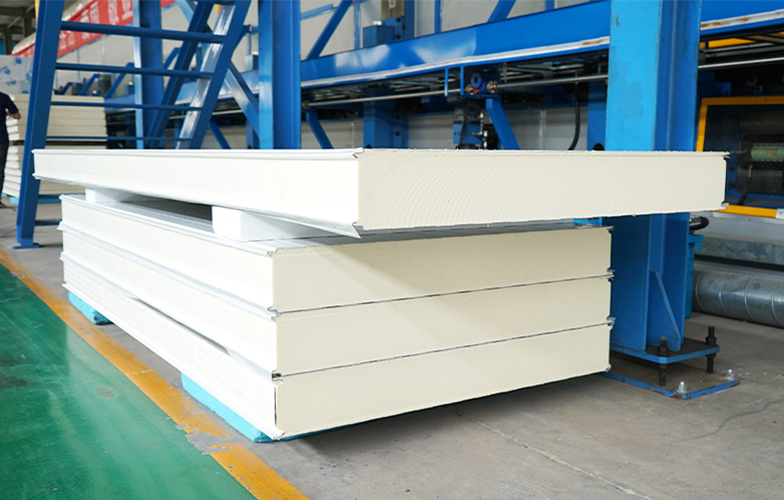

Designed to meet diverse project requirements, these panels can be customized in thickness, color, steel coating, foam core material, and joint system.

As specialists in customized sandwich panels for cold room partition wall, we produce panels with stable thermal performance, airtight joint connections, and high-density insulation materials.

Our customized sandwich panels walls are widely used in hospitals, warehouses, industrial facilities, modular buildings, and cold storage projects.

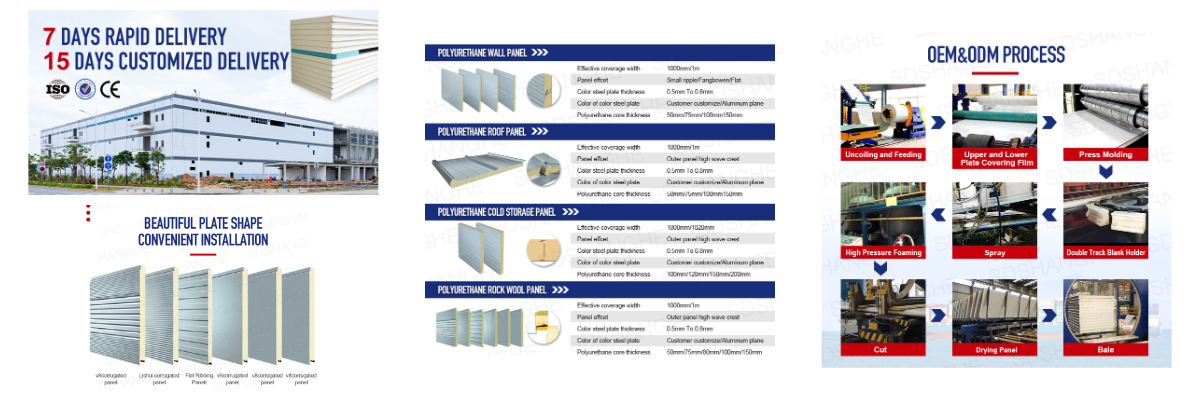

We operate a modern OEM factory dedicated to producing high-quality customized wall sandwich panel systems.

Fully automated continuous production lines

High-pressure PU/PIR foaming system

CNC-controlled cutting and dimension customization

Automated steel roll forming and profiling machines

ISO-certified manufacturing standards

High-volume OEM/ODM support

Thermal performance testing

Core density testing

Adhesion strength testing

Steel coating corrosion resistance tests

Fire resistance classification

Dimensional accuracy checks

As a reliable supplier of customized sandwich panel systems, we provide flexible MOQ, global export services, and project-based customization.

| Item | Specification |

Core Material Options | PU, PIR, EPS, Rock Wool |

Density | PU/PIR 38–45 kg/m³, Rock Wool 100–150 kg/m³ |

Thermal Conductivity | PU/PIR ≤0.022 W/(m·K), Rock Wool ≤0.038 W/(m·K) |

Panel Thickness | 40 mm – 200 mm (customized) |

Standard Width | 950 mm, 960 mm, 1000 mm |

Length | Up to 12 meters (customizable) |

Steel Material | PPGI, GI, PPGL, Stainless Steel |

Steel Thickness | 0.35–0.7 mm |

Joint System | Tongue-and-groove, cam-lock, concealed-fix |

Surface Options | Flat, ribbed, micro-rib, antibacterial finish |

Fire Rating | PU/PIR B1–B2, Rock Wool A1 |

Applications | Cold rooms, walls, partition walls, exterior cladding, modular buildings |

Cold room partition walls

Industrial and commercial wall insulation

Prefabricated building panels

Warehouse and logistics walls

Clean room panels

Modular housing and mobile buildings

Exterior wall cladding for energy-efficient buildings

Professional OEM production with full customization options

Advanced manufacturing lines ensuring consistent quality

Strong insulation performance with multiple core material choices

Global export capability with fast delivery

Competitive factory direct pricing

Technical support and installation guidance for all projects

A1 Yes, we provide full customization for panel dimensions and all RAL colors.

A2 Yes, as experts in customized sandwich panels for cold room partition wall, we offer specialized PU/PIR options with better insulation.

A3 PU, PIR, EPS, and rock wool are available depending on insulation and fire-rated requirements.

A4 Yes, we are an OEM manufacturer offering flexible production for large engineering projects.

A5 Yes, we export as a global customized wall sandwich panel supplier to over 60 countries.