Excellent Thermal Insulation Performance

High-density polyurethane (PU) core provides superior thermal insulation, effectively reducing energy consumption for industrial and commercial buildings.

Lightweight Yet High Structural Strength

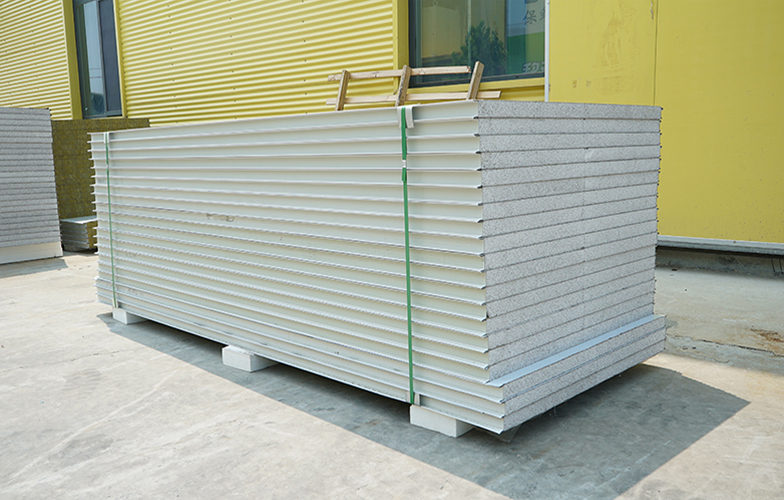

Compared with traditional masonry or concrete walls, PU sandwich panels significantly reduce building load while maintaining strong structural integrity.

Fast Installation & Labor Cost Saving

Modular design allows quick assembly, reducing installation time by up to 40–60% compared to conventional construction methods.

Excellent Airtightness & Moisture Resistance

Closed-cell PU core structure prevents moisture penetration and condensation, suitable for cold rooms and humid environments.

Wide Application Compatibility

Suitable for walls, roofs, ceilings, and enclosure systems across industrial, commercial, and prefabricated buildings.

Low Maintenance & Long Service Life

Corrosion-resistant metal surfaces combined with stable PU insulation ensure long-term durability with minimal maintenance.

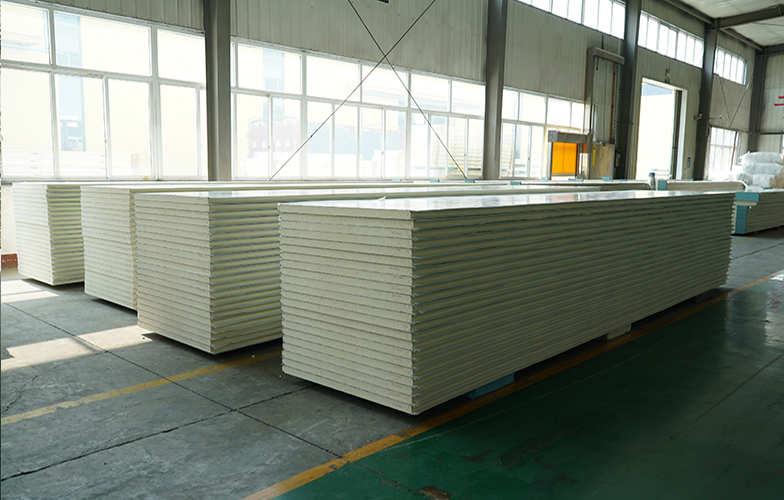

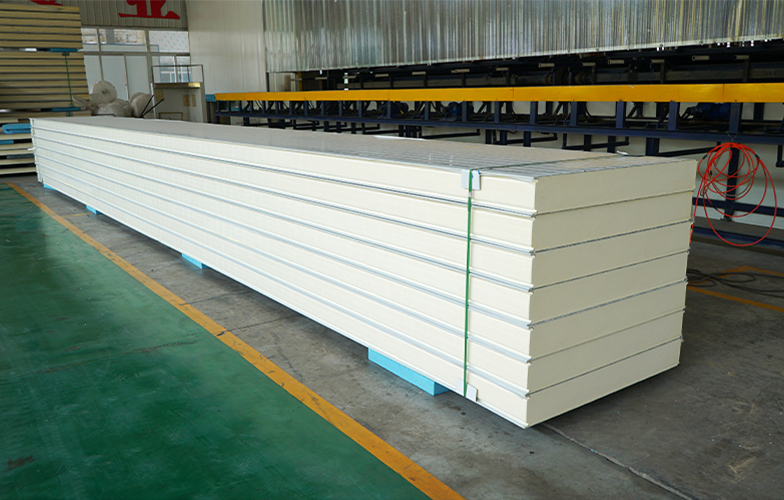

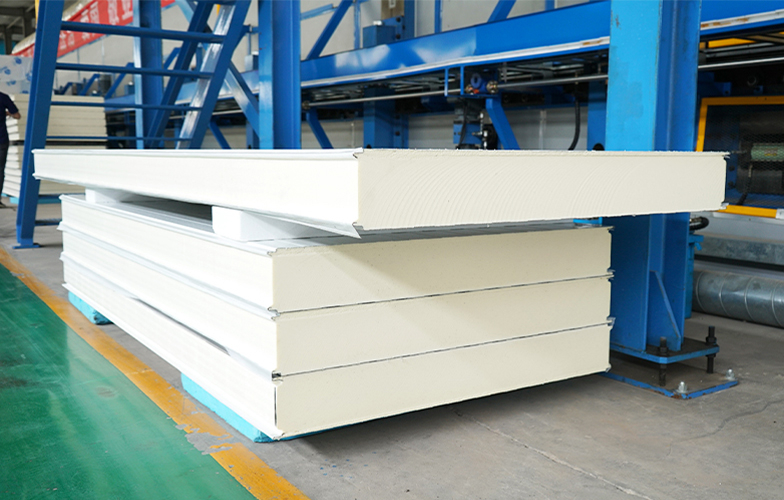

PU Sandwich Panel is a high-performance insulated building material composed of two metal sheets bonded to a rigid polyurethane foam core. Designed to meet the requirements of modern industrial and prefabricated construction, PU sandwich panels provide an excellent balance between thermal insulation, mechanical strength, and construction efficiency.

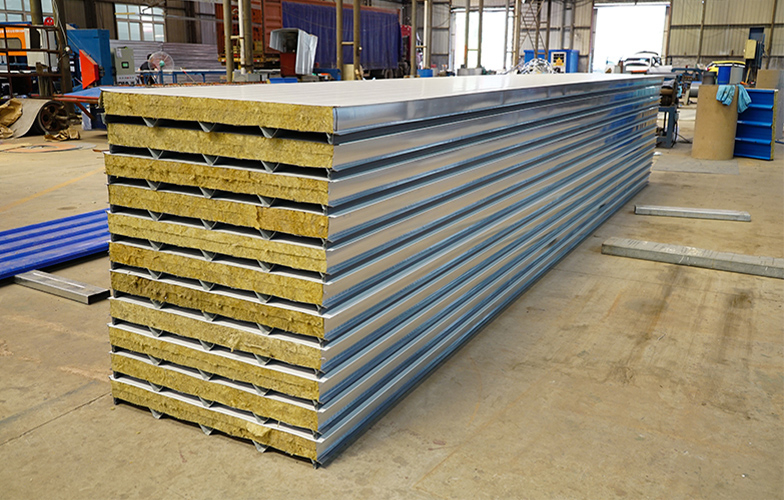

The closed-cell polyurethane core offers outstanding thermal resistance, making the panel an ideal solution for energy-efficient buildings. Compared with traditional insulation materials, PU insulation delivers lower thermal conductivity, enabling thinner panels to achieve superior insulation performance.

PU sandwich panels are widely used in industrial buildings, warehouses, cold storage facilities, prefabricated houses, clean rooms, and commercial structures. Their lightweight nature and modular design significantly reduce construction time and labor costs while ensuring consistent quality and performance.

High thermal insulation efficiency with low thermal conductivity

Lightweight structure reduces foundation and steel structure costs

Excellent fire resistance options available according to project requirements

Strong bonding between metal sheets and PU core ensures long-term stability

Factory-controlled production guarantees consistent panel quality

Smooth and flat surface suitable for both functional and architectural applications

| Item | Specification |

Panel Type | PU Sandwich Panel |

Core Material | Rigid Polyurethane (PU) Foam |

Panel Thickness | 50mm / 75mm / 100mm / 120mm / 150mm |

Metal Sheet Thickness | 0.3mm – 0.8mm |

Panel Width | 950mm / 1000mm (customizable) |

Panel Length | Customizable up to 12,000mm |

Thermal Conductivity | ≤ 0.024 W/(m·K) |

Density of PU Core | 38–45 kg/m³ |

Fire Rating | Optional fire-resistant grades |

Surface Material | Color steel / Galvanized steel / Aluminum |

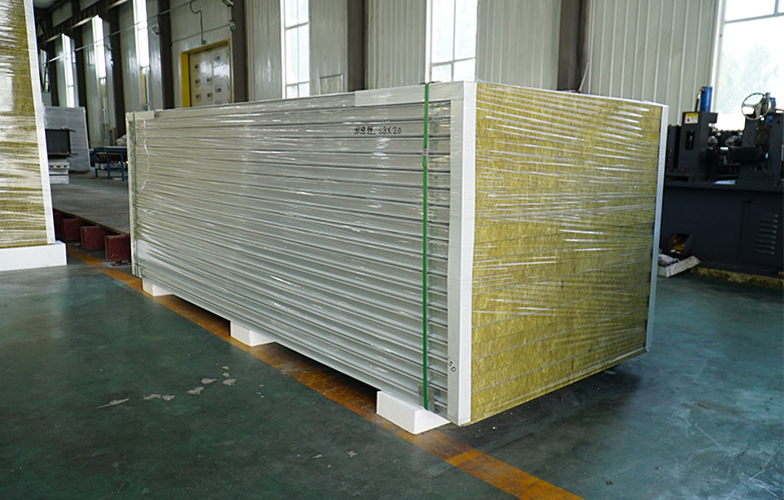

Installation Method | Tongue & groove / concealed fixing |

Application | Wall / Roof / Ceiling |

PU sandwich panels are suitable for a wide range of building applications, including but not limited to:

Industrial Plants & Factories

Used for external walls and roofing systems to ensure insulation and structural efficiency.

Warehouses & Logistics Centers

Ideal for large-span buildings requiring fast installation and temperature control.

Cold Storage & Refrigeration Facilities

Excellent thermal performance ensures stable internal temperatures and reduced energy loss.

Prefabricated & Modular Buildings

Lightweight panels simplify transportation and on-site assembly.

Commercial & Utility Buildings

Suitable for workshops, showrooms, temporary offices, and service buildings.

PU sandwich panels offer a cost-effective and technically advanced solution for modern construction needs. Their superior insulation properties, combined with fast installation and long service life, make them a preferred choice for engineers, contractors, and project developers seeking efficiency and reliability.

By choosing PU sandwich panels, projects benefit from reduced construction timelines, lower operational energy costs, and consistent quality control.

Q1: What is the main advantage of PU sandwich panel compared to EPS or rock wool panels?

A: PU sandwich panels provide lower thermal conductivity, meaning better insulation performance with thinner panel thickness.

Q2: Can PU sandwich panels be used for both walls and roofs?

A: Yes, PU sandwich panels are suitable for wall, roof, and ceiling applications depending on panel design and installation method.

Q3: Are PU sandwich panels suitable for cold storage buildings?

A: Yes, the closed-cell PU core makes them especially suitable for cold rooms and temperature-controlled environments.

Q4: What thickness should be chosen for industrial buildings?

A: Commonly used thicknesses are 50mm to 100mm, depending on insulation and structural requirements.

Q5: Can panel size and surface material be customized?

A: Yes, panel length, thickness, and surface materials can be customized according to project needs.