Low Thermal Conductivity Core System

The rigid PU foam core adopts a closed-cell structure with extremely low thermal conductivity, effectively reducing heat transfer and improving overall building energy efficiency.

High Panel Flatness and Dimensional Stability

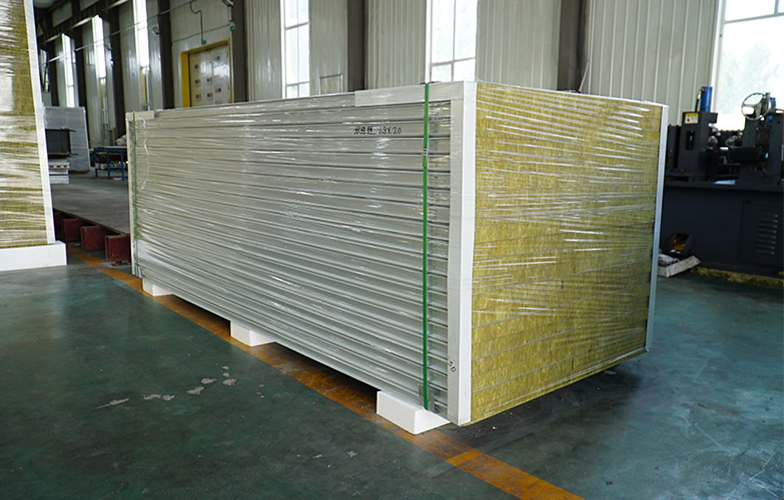

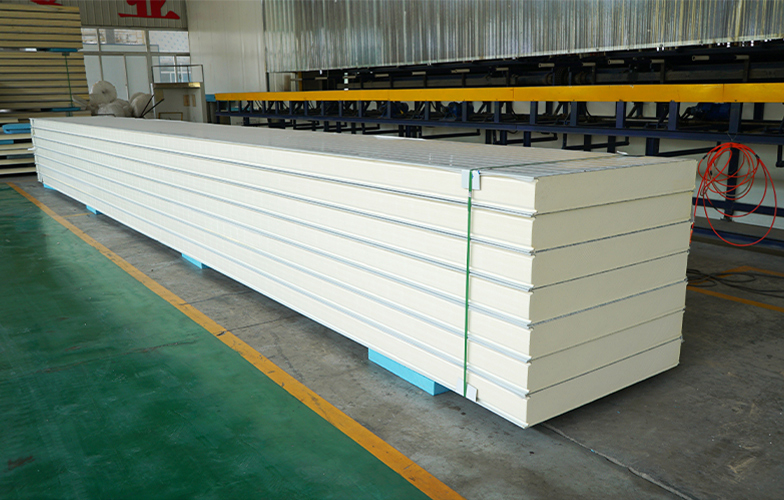

Precision-controlled lamination process ensures uniform thickness and excellent flatness, reducing deformation during transportation and installation.

Strong Composite Bonding Structure

The metal skins and PU core are chemically bonded into a single structural unit, providing reliable shear strength and long-term performance stability.

Fast Enclosure Construction Efficiency

Modular panel design allows large-area installation with fewer joints, significantly shortening enclosure construction cycles.

Moisture Resistance and Condensation Control

Closed-cell PU structure prevents moisture absorption, minimizing condensation risk in temperature-controlled or humid environments.

Adaptability to Multiple Building Systems

Compatible with steel structure buildings, prefabricated systems, and modular construction solutions.

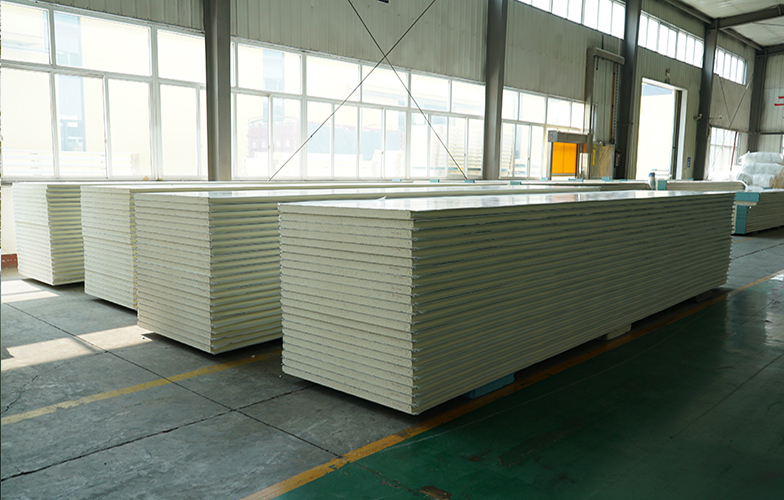

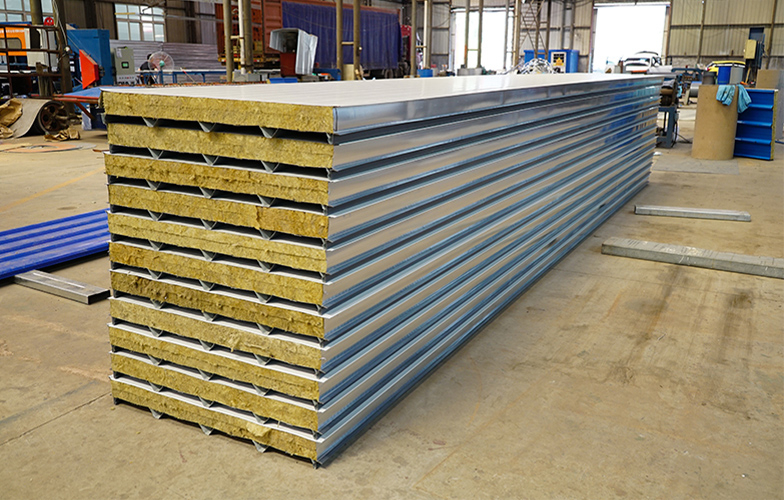

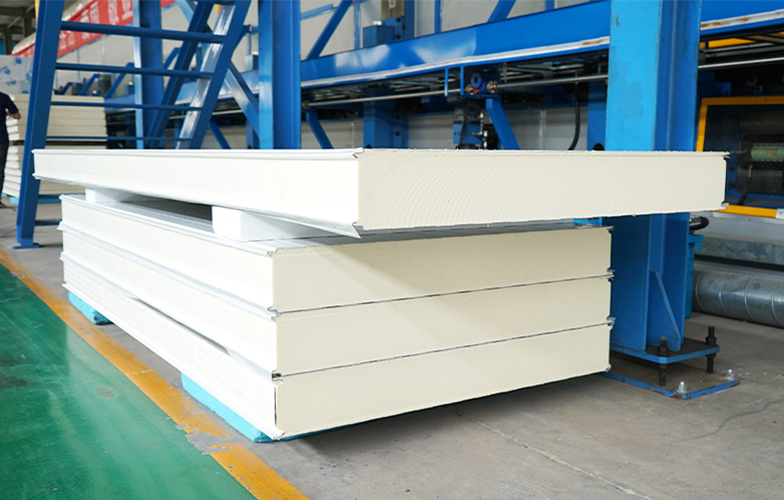

PU Sandwich Panel is a high-performance insulated enclosure material designed for modern industrial and prefabricated building systems. The panel consists of two metal sheets bonded to a rigid polyurethane (PU) foam core through continuous production technology, forming a stable composite structure with excellent insulation and mechanical properties.

The polyurethane core plays a critical role in thermal performance. Due to its closed-cell structure, PU insulation significantly limits heat transfer, helping buildings maintain stable internal temperatures while reducing energy consumption. Compared with traditional insulation materials, PU offers superior insulation efficiency with reduced thickness, making it particularly suitable for projects with strict space or energy-saving requirements.

From a structural perspective, PU sandwich panels provide a balanced combination of lightweight design and mechanical strength. The composite bonding between the metal facings and the PU core distributes loads evenly across the panel surface, improving resistance to wind pressure and structural deformation. This makes the panel suitable for both vertical and horizontal enclosure applications.

Installation efficiency is another key advantage. PU sandwich panels are factory-produced with precise dimensions and consistent quality, allowing rapid on-site installation. Large panel sizes reduce the number of joints, improving airtightness and shortening construction schedules. This efficiency is especially valuable in industrial projects where time control is critical.

In addition to insulation and strength, PU sandwich panels offer excellent moisture resistance. The closed-cell PU core prevents water absorption, while the metal surfaces protect the panel from environmental exposure. This combination reduces the risk of corrosion, mold growth, and insulation degradation over time.

PU sandwich panels are widely applied in industrial plants, logistics facilities, cold storage buildings, prefabricated houses, and various functional buildings. Their versatility allows designers and contractors to use a single panel system across different building areas, simplifying material management and construction planning.

| Parameter | Specification |

Product Type | PU Sandwich Panel |

Core Material | Rigid Polyurethane (PU) |

Panel Thickness | 50mm / 75mm / 100mm / 120mm / 150mm |

PU Core Density | 38–45 kg/m³ |

Thermal Conductivity | ≤ 0.024 W/(m·K) |

Metal Sheet Thickness | 0.3mm – 0.8mm |

Panel Width | 950mm / 1000mm |

Panel Length | Customizable |

Surface Options | Color steel / Galvanized steel / Aluminum |

Joint System | Tongue & groove / concealed joint |

Installation Position | Wall / Roof / Ceiling |

Industrial Buildings

Used as external and internal enclosure panels for factories and production facilities.

Warehouses & Logistics Centers

Suitable for large-span buildings requiring fast construction and thermal control.

Cold Storage & Temperature-Controlled Facilities

Excellent insulation performance ensures energy efficiency and temperature stability.

Prefabricated & Modular Buildings

Lightweight structure supports fast assembly and transportation efficiency.

Utility & Auxiliary Buildings

Applied in workshops, equipment rooms, and service buildings.

Q1: What makes PU sandwich panels suitable for energy-efficient buildings?

A: The low thermal conductivity and closed-cell structure of the PU core significantly reduce heat transfer.

Q2: Can PU sandwich panels be used for both vertical and horizontal installation?

A: Yes, they are suitable for walls, roofs, and ceilings depending on structural design.

Q3: Are PU sandwich panels resistant to moisture?

A: Yes, the closed-cell PU core minimizes moisture absorption and condensation risks.

Q4: How does PU compare to other insulation cores in terms of thickness efficiency?

A: PU provides better insulation performance with thinner panel thickness.

Q5: Can dimensions and surface materials be adjusted for different projects?

A: Panel thickness, length, and surface materials can be selected according to project requirements.