Factory-Built Precision:Manufactured under controlled conditions for consistent quality and finish.

Fast Project Delivery:Short production time and simple installation reduce overall build schedule.

Durable Steel Structure:Reinforced framework ensures strength and structural stability.

Energy-Efficient Design:Insulated panels improve temperature control and indoor comfort.

Cost Predictability:Pre-fabrication limits unexpected labor and material expenses.

Flexible Layout Options:Units can be configured as living, working, or commercial spaces.

Low Maintenance:Long-life materials require minimal repair and upkeep.

Product Details

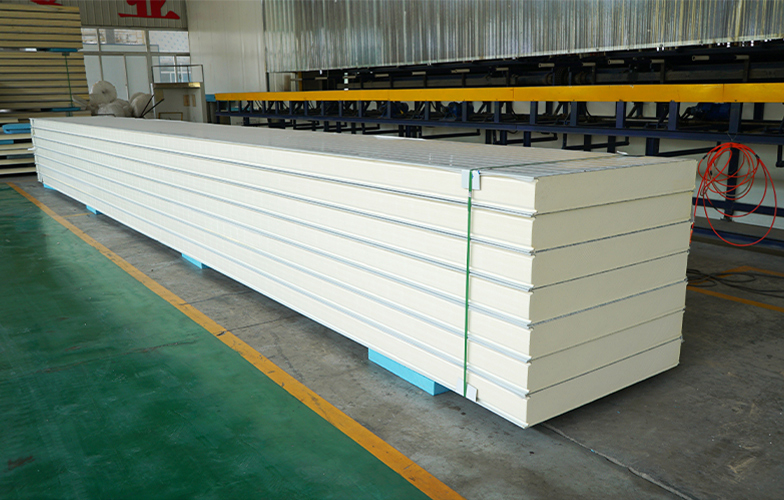

Prefabricated container houses is a modular building solution engineered for large-scale projects that require standardized quality, fast deployment, and efficient transportation. Unlike fully assembled container buildings, this system is delivered in a knock-down format, allowing all structural and enclosure components to be packed flat and assembled on-site. Thisapproach significantly reduces shipping volume and provides greater flexibility for international project deployment.

Key Features

All load-bearing components are manufactured under factory-controlled conditions to ensure dimensional accuracy and stable performance. The modular steel structure is designed to support both single-unit use and multi-unit combination, making it adaptable to different project layouts.

One of the main engineering advantages of the flat pack prefab container house lies in its assembly efficiency. Structural members, wall panels, and roof systems are pre-designed with standardized connection points. This allows on-site installation using basic tools, without the need for specialized machinery. As a result, construction time is significantly reduced compared with traditional building methods.

From a functional standpoint, the flat pack container building supports a wide range of interior configurations. Units can be customized with sleeping areas, sanitary facilities, office spaces, or storage zones. Electrical wiring routes and optional plumbing interfaces are planned during production, ensuring compliance with safety requirements and reducing on-site installation risks.

In terms of project value, the flat pack modular container house is ideal for phased construction and repeat deployment. Its standardized design allows consistent quality across large quantities, while flexible configuration options make it adaptable to different applications. This makes it particularly suitable for infrastructure projects, workforce accommodation, and temporary building solutions where speed and reliability are critical.

Why Choose Our Prefab Container Homes?

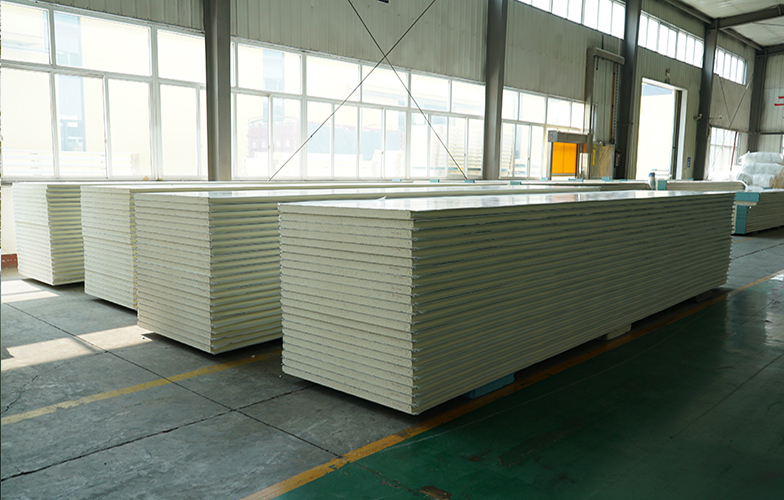

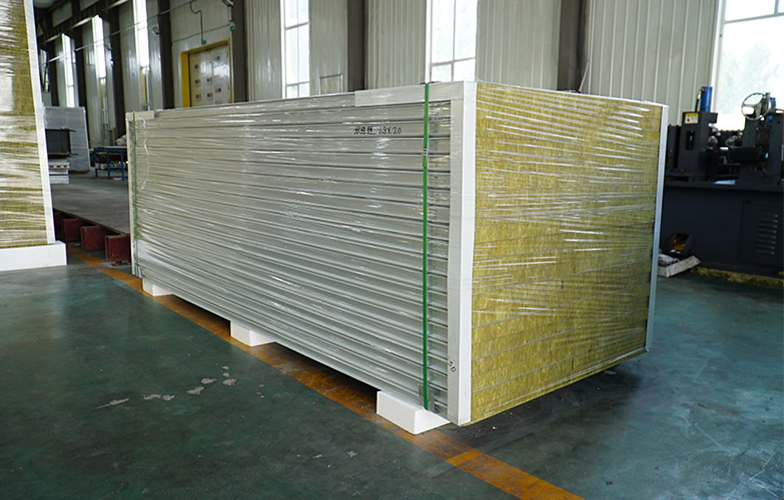

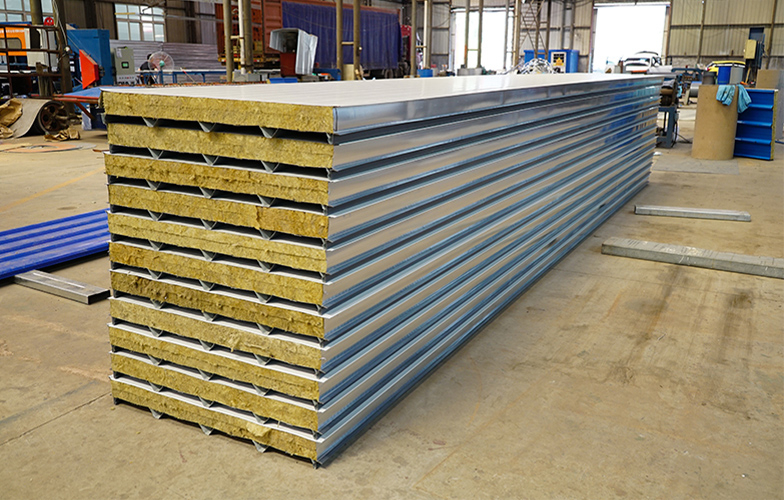

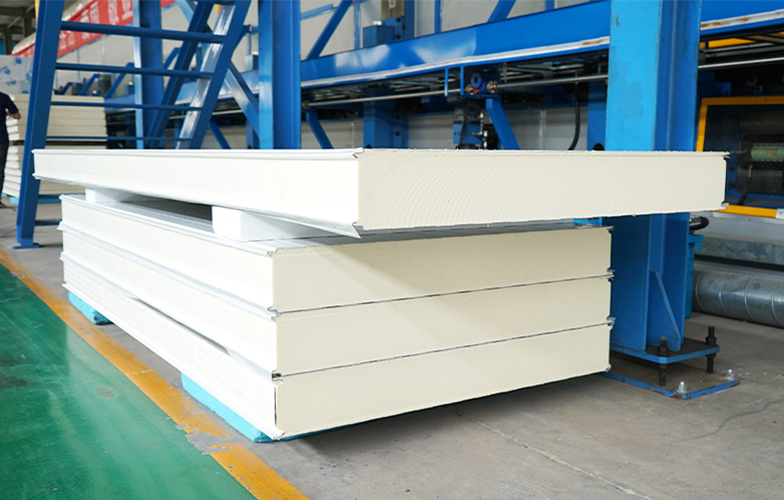

Premium Quality:All steel components are galvanized to improve corrosion resistance and extend service life. The modular connection system ensures accurate alignment during assembly, maintaining structural integrity even after multiple installations.Wall and roof systems are manufactured using insulated sandwich panels, which provide effective thermal insulation and sound reduction. This helps improve indoor comfort while meeting basic energy efficiency requirements. The floor system is engineered for durability and daily use, making the flat pack container building suitable for both residential and commercial applications.

Product Applications

Prefabricated container houses cater to various sectors and use cases, including:

Installation is performed by assembling the steel frame, fixing wall and roof panels, and securing all connections with bolts. Because all components are pre-engineered, installation time is predictable and can be completed by a small team. This makes the flat pack prefab container house especially suitable for projects with tight schedules or limited on-site labor availability.

Product Specifications

Option Size | 20 feet, 40 feet, etc. We also have a special size of 2.9 meters high |

Main materials | Galvanized steel structure with sandwich panel walls, doors and windows, etc |

Weight | 1.8T |

Service life | 30-40 years |

Color | White, Blue, Green, Brown or Custom |

Columns | 3mm hot galvanized steel structure |

Wall | 50/75/100mm EPS/Rock woll/PU sandwich panel |

Door | Made of steel/aluminum frame,dimension W870*H2040mm,furnish with a handle lock with 3 keys,or sliding glass door W1500*2000mm. |

Window | Made of PVC/aluminum fame,dimension W930*H1100mm,glazed with double glass in a thickness of 5/8/5mm or custom |

Connection kits | PVC connection kit for ceiling, floor and walls |

Electricity | 3C/CE/CL/SAA Standard,with distribution box,lights,switch,sockets,etc. |

Optional Accessories | Furniture,sabnitary,kitchen,A/C,electrical appliance for accomodation,office,dormitory,toliet,kitchen,bathroom,shower,steel |

Advantage | (1) Fast installation: 2 hours/set, save labor cost; |

Model NO. | Mobile House | Product Type | Flat Pack Container |

Application | Office Building | Place of Origin | Shandong, China |

Brand Name | Sh | Design Style | Modern |

Product Name | Flat Pack Container | Keyword | Modular Container Home |

Advantage | Eco Friendly, Fast Install, Wind Proof, Light Weight | Service Life | At Least 30 Years |

Structure | Q235/Q345 Light Steel Frame | Applications | Office Buildings, Hotel, Mall, Mining Area, etc |

Floor | MGO Board, Fiber Cement Board, PVC Board | Wall | Sandwich Panel Wall |

Standard Size | Custom Requirement | Color | Customizable Patterns and Colors |

Transport Package | Standard Exporting Packing | Specification | 20ft OR 40ft, Customized |

Trademark | SH | Origin | China |

HS Code | 9406900090 | Production Capacity | 6000 Unit/Units Per Month |